NBR PVC RUBBER FOAM ISOLAASJEBLÊD

Produktbeskriuwing:

Dit produkt kin bedekt wurde mei ferskate soarten folies (aluminiumfolie of glêsdoek) en hat in fabryksmjittich oanbrochte selslijmende efterkant. De ynstallaasjetiid wurdt mei mear as 40% fermindere troch it gemak fan snijen en de rappe hechting fan it materiaal.

Standert diminsje

| Kingflex Dimension | |||||||

| Thikke | Widde 1m | Wdiameter 1.2m | Wdiameter 1.5m | ||||

| Inch | mm | Grutte (L * B) | ㎡/Rôlje | Grutte (L * B) | ㎡/Rôlje | Grutte (L * B) | ㎡/Rôlje |

| 1/4" | 6 | 30 × 1 | 30 | 30 × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | 20 × 1 | 20 | 20 × 1.2 | 24 | 20 × 1.5 | 30 |

| 1/2" | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| 3/4" | 19 | 10 × 1 | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | 8 × 1 | 8 | 8 × 1.2 | 9.6 | 8 × 1.5 | 12 |

| 1 1/4" | 32 | 6 × 1 | 6 | 6 × 1.2 | 7.2 | 6 × 1.5 | 9 |

| 1 1/2" | 40 | 5 × 1 | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Technysk gegevensblêd

| Kingflex Technyske gegevens | |||

| Besit | Ienheid | Wearde | Testmetoade |

| Temperatuerberik | °C | (-50 - 110) | GB/T 17794-1999 |

| Dichtheidsberik | Kg/m3 | 45-65 kg/m3 | ASTM D1667 |

| Wetterdamppermeabiliteit | Kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Part 2 1973 |

| μ | - | ≥10000 | |

| Termyske geliedingsfermogen | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

|

|

| ≤0,032 (0 °C) |

|

|

|

| ≤0,036 (40 °C) |

|

| Brânwurdearring | - | Klasse 0 & Klasse 1 | BS 476 Diel 6 diel 7 |

| Flammefersprieding en rookûntwikkelingsyndeks |

| 25/50 | ASTM E 84 |

| Soerstofyndeks |

| ≥36 | GB/T 2406, ISO4589 |

| Wetteropname,% per folume | % | 20% | ASTM C 209 |

| Diminsjestabiliteit |

| ≤5 | ASTM C534 |

| Skimmelresistinsje | - | Goed | ASTM 21 |

| Ozonresistinsje |

| Goed | GB/T 7762-1987 |

| Wjerstân tsjin UV en waar |

| Goed | ASTM G23 |

Foardielen fan produkt

Foar it foarkommen fan kondensaasje en it beheinen fan enerzjyferlies wêr't pipen en kanalen, koelers en airconditioningapparatuer nedich binne.

Ferminderet effisjint waarmtestream op waarme systemen, kanaalwurk, grutte piipwurk, tanks en fittingen.

Us Bedriuw

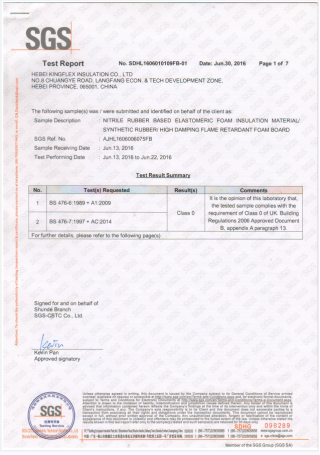

Bedriuwsertifikaat

Underdiel fan ús sertifikaten

Produktkategoryen

-

Telefoan

-

E-post

-

Whatsapp